2022-12-02

Agility and efficiency in a modern form

New industrial brake series from RINGSPANN sets standards in design and number of switching operations

The electromagnetic disc brakes of the RINGSPANN series EV/EH are regarded worldwide as a proven standard solution for the implementation of restraining and emergency stop systems in mechanical and plant engineering. Now, however, the company is presenting a new generation of electric brakes that set standards in terms of switching performance, energy efficiency and design. They bear the series designation MV, have an innovative locking mechanism and apply clamping forces of up to 25,000 N to the disc.

Bad Homburg, December 2022. – Their closed shape follows the rules of modern industrial design, their high switching rates open up extended performance and flexibility potentials for the user and their energy requirements are only minimal. In addition, they have intelligent electronics and work with a highly efficient closing mechanism. This refers to the new spring-operated and electromagnetically released disc brakes of the MV series from RINGSPANN. Designed for clamping forces of up to 25,000 N and available as standard for brake disc diameters from 300 to 710 mm, they cover a wide range of holding, emergency stop and deceleration applications in mechanical and plant engineering. Their specific fields of application include machine tool construction, turbine, fan and blower technology, winch and winding technology, the wind power industry and general drive technology. They are particularly attractive for those designers who want to spare users and operators the high installation and maintenance costs of hydraulic and pneumatic brake systems.

“Big leap in innovation”

From a purely chronological point of view, the electromagnetic disc brakes of the new MV series could also be seen as a further development of the widely established EV/EH e-brake series from RINGSPANN. “However, the leap in innovation in this case is so great that we can speak of a new generation of brakes with a clear conscience”, says Franz Eisele, who heads the brakes and clutches division at RINGSPANN. In addition to the modern industrial design of the brakes, two technical aspects in particular are decisive for this view: their extraordinary switching performance and a new closing technology. With up to 550 shifts per hour in 230 VAC operation and up to 450 shifts per hour in 400 VAC operation as standard, MV brake callipers from RINGSPANN are probably among the fastest and most agile electric disc brakes on the world market. In combination with its closed, robust design, it predestines it for use in demanding environments with frequent braking. Ongoing test runs by RINGSPANN suggest that a B10d value of several million switching cycles will be achieved for the MV series. In addition, the new, now patented locking mechanism gives the brakes an above-average air gap with only minimal loss of spring force during bridging of the gap. “As a result, the new MV series covers an exceptionally wide range of applications in the field of electromagnetic brakes,” explains Franz Eisele. Also worth mentioning is the integrated floating mounting of the brakes, which compensates for small axial asymmetries of the brake disc.

Economical and intelligent

RINGSPANN offers the new MV disc brakes for operating voltages from 220 to 240 VAC and 380 to 480 VAC. In terms of energy efficiency, they build on the excellent values of the EV/EH series. An inductive encoder for sensory monitoring of the brake function (open/closed) and the degree of wear of the brake pad can also be attached as an option. Friction block replacement is done in a few simple steps and without dismantling the brake. Braking torque and clamping force can be easily and precisely adjusted to the application via an adjusting nut. Another option is a lever for manual, controlled opening of the brake. “With a view to modern Industry 4.0 applications, we have also ensured that the sensor monitoring functions can be integrated into higher-level safety and control systems,” emphasizes Franz Eisele. All these are important contributions to improving the efficiency, operational safety and availability of industrial drive systems.

Expanded scope for designers

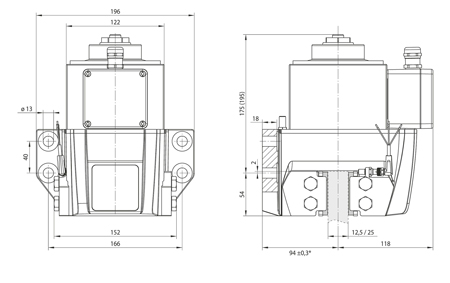

In addition to its previous portfolio of electric disc brakes, RINGSPANN can now provide designers of drive systems with six further basic types of innovative e-brakes in the new MV series. They are now available in the three frame sizes 022, 033 and 044 with clamping forces from 4 to 25 kN and can be used very flexibly as stopping, emergency stop or service brakes. The frame size 022 is suitable for brake discs of thicknesses of 12.5 and 20 mm, size 033 for 12.5 and 25 mm thick discs and for size 044 the brake discs can be 25 and 30 mm thick. In combination with thicker brake discs, the MV brakes of sizes 033 and 044 can also be used for thermally sensitive braking processes. Design advantages also result from the compact design of the RINGSPANN brakes and their low dead weights. “Both prove to be an advantage for all cases in which the brake is an integrated part of a moving unit,” explains Franz Eisele.

RINGSPANN offers the new MV brakes in versions with manual wear adjustment (type FEM) as well as in a variant with automatic wear adjustment (type FEA). While manual adjustment is primarily suitable for holding applications or applications with rather infrequent braking, automatic wear adjustment is primarily recommended for service brakes with demanding deceleration tasks. ms

A great deal of safety for just a little energy

The electronics of the electric disc brakes from RINGSPANN work extremely reliably and ensure the functional operation of the brake. It is redundantly protected against voltage peaks and in the event of a mains fault, the functionality of the generously dimensioned switching transistors is guaranteed at all times. In addition, RINGSPANN was able to reduce the required tightening power of the latest brake generation by up to 20 percent. The magnetic circuit was optimized using modern FEM calculations. The result is very compact magnets and an optimal interaction of magnet and electronics.

What does B10 and B10d value mean?

The B10 value is a statistical factor determined from lifetime tests with a corresponding number of specimens. It stands for the average number of switching cycles or cycles of a unit, after which a maximum of 10 percent failures can be expected. The value is valid under defined conditions; failure refers to exceeding specified limit values (switching time, leakage...). It should be noted that a component can fail even before the B10 value is reached. The stated probability of survival therefore does not constitute a manufacturer's warranty. According to ISO 13849-1, the B10d value indicates the number of switching cycles or cycles after which dangerous failures occur in 10 percent of the units considered (“d” stands for “dangerous”). The value is relevant for risk and hazard analyses as well as for the evaluation of machine or plant safety.