2016-02-11

Maximum consistency with minimum wear

RINGSPANN presents new friction torque limiters for heavy-duty applications of up to 60,000 Nm

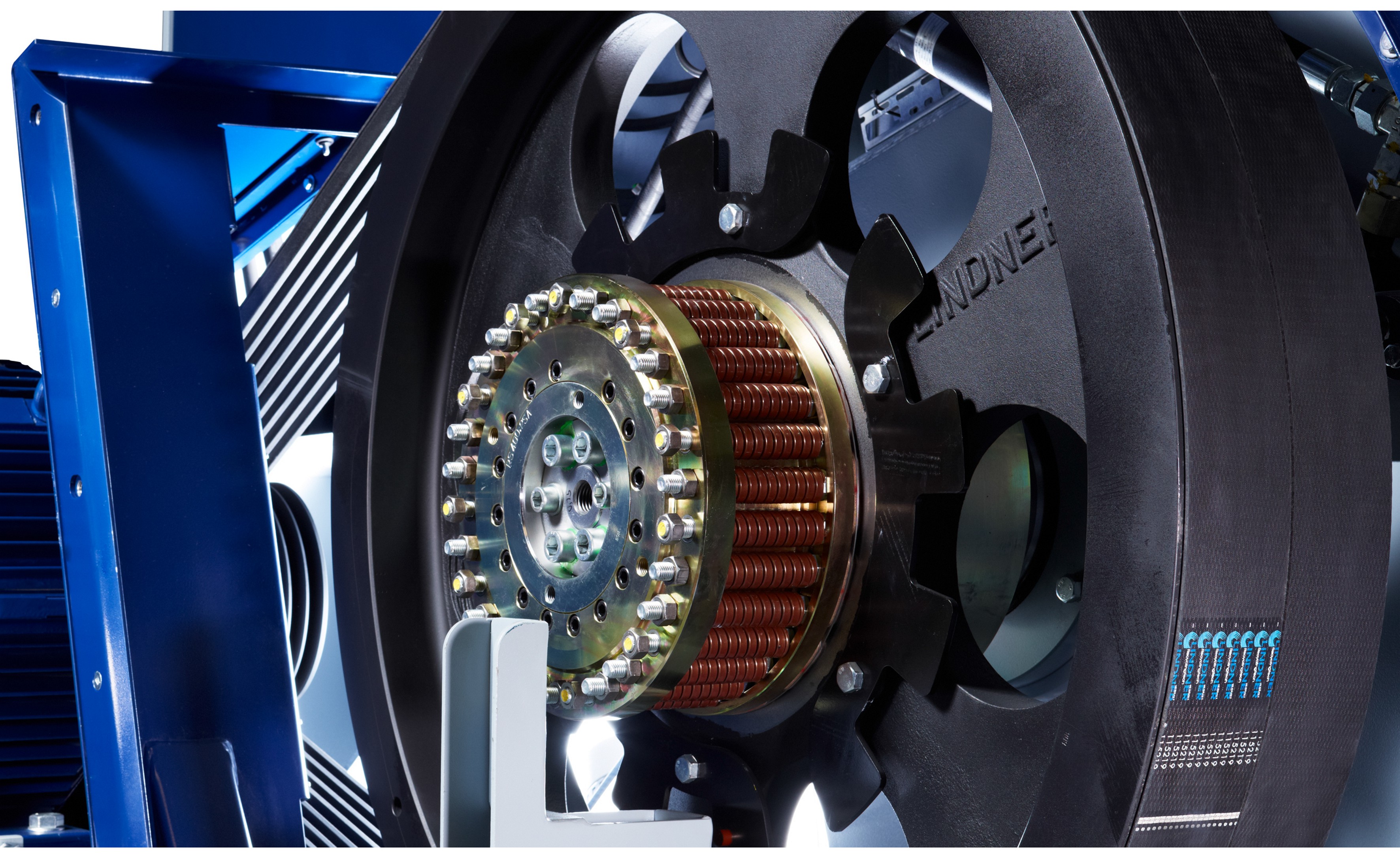

With the friction torque limiters of its RIMOSTAT® series, RINGSPANN has been setting standards in this area of overload protection for many years now. With its new high-performance friction torque limiter RSHD, the manufacturer is now extending its offering to include innovative overload protection for heavy-duty applications. The RIMOSTAT® RSHD by RINGSPANN earns brownie points for its extremely constant slipping torque, a temperature resistance up to 800° C and excellent wear properties under high load. It is therefore an ideal solution for use in construction machines, shredding mills and conveyor systems.

Bad Homburg, February 2016. RINGSPANN has developed its new high-performance friction torque limiter type RSHD as customised overload protection for heavy-duty applications, as are typical in the work of construction machines, conveying systems, shredders or even ship suction dredgers. The torque limiter, which is fitted with first-class components and designed in line with the manufacturer’s RIMOSTAT® principle, is able to keep even the highest slipping torques of up to 60,000 Nm constant over a very long operating time with minimum wear. In addition, the new RIMOSTAT® RSHD by RINGSPANN stands out for its high dry running stability at working temperatures of up to 800° C. Plant and machinery constructors thus get highly efficient and premium-class overload protection, with which they can ultimately improve the competitiveness of their heavy-duty units considerably. For with the RIMOSTAT® RSHD by RINGSPANN, they can permanently lower the risk of damage and failure of their drive units and reduce their repair and maintenance costs to a minimum.

Where great forces prevail

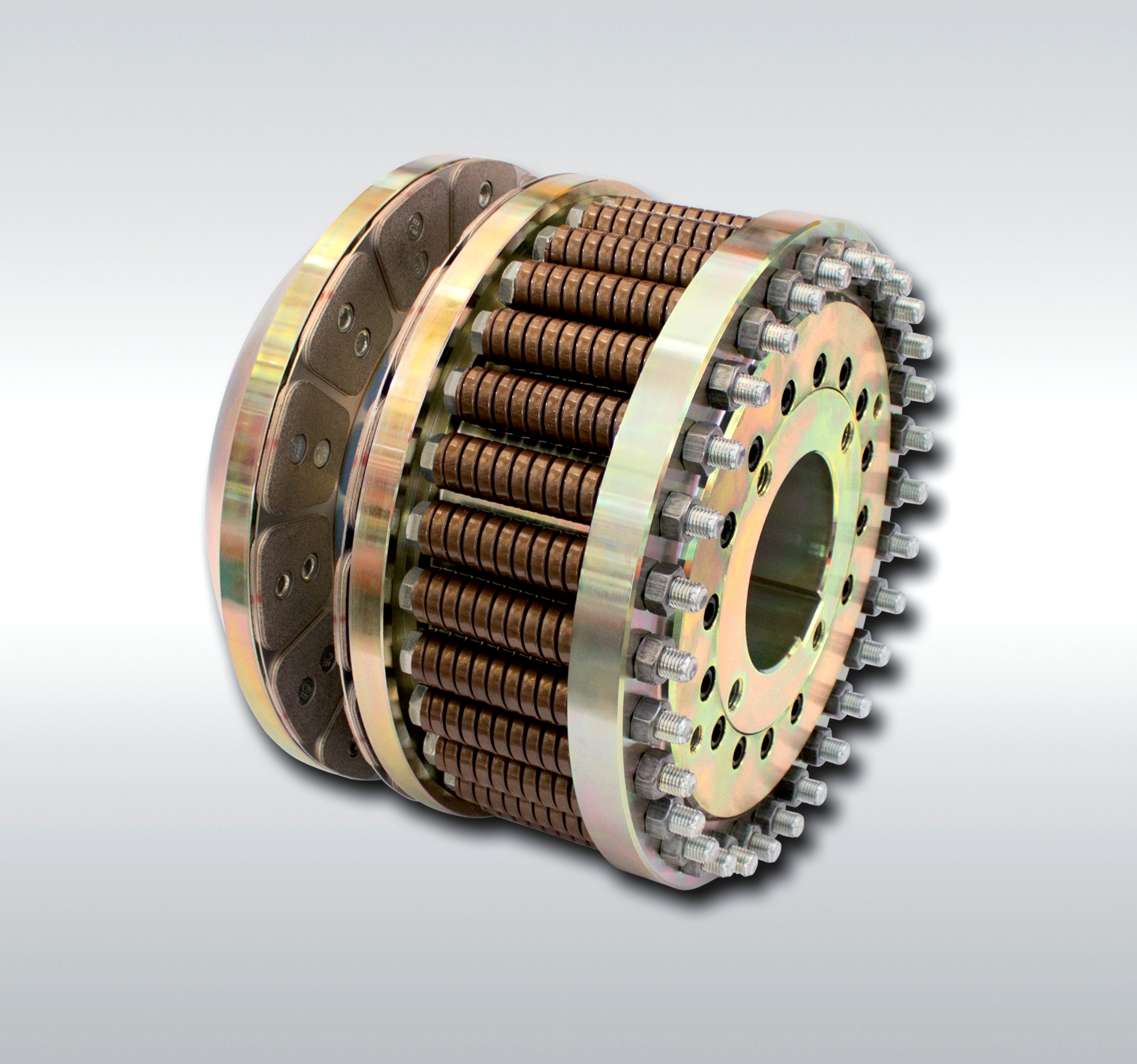

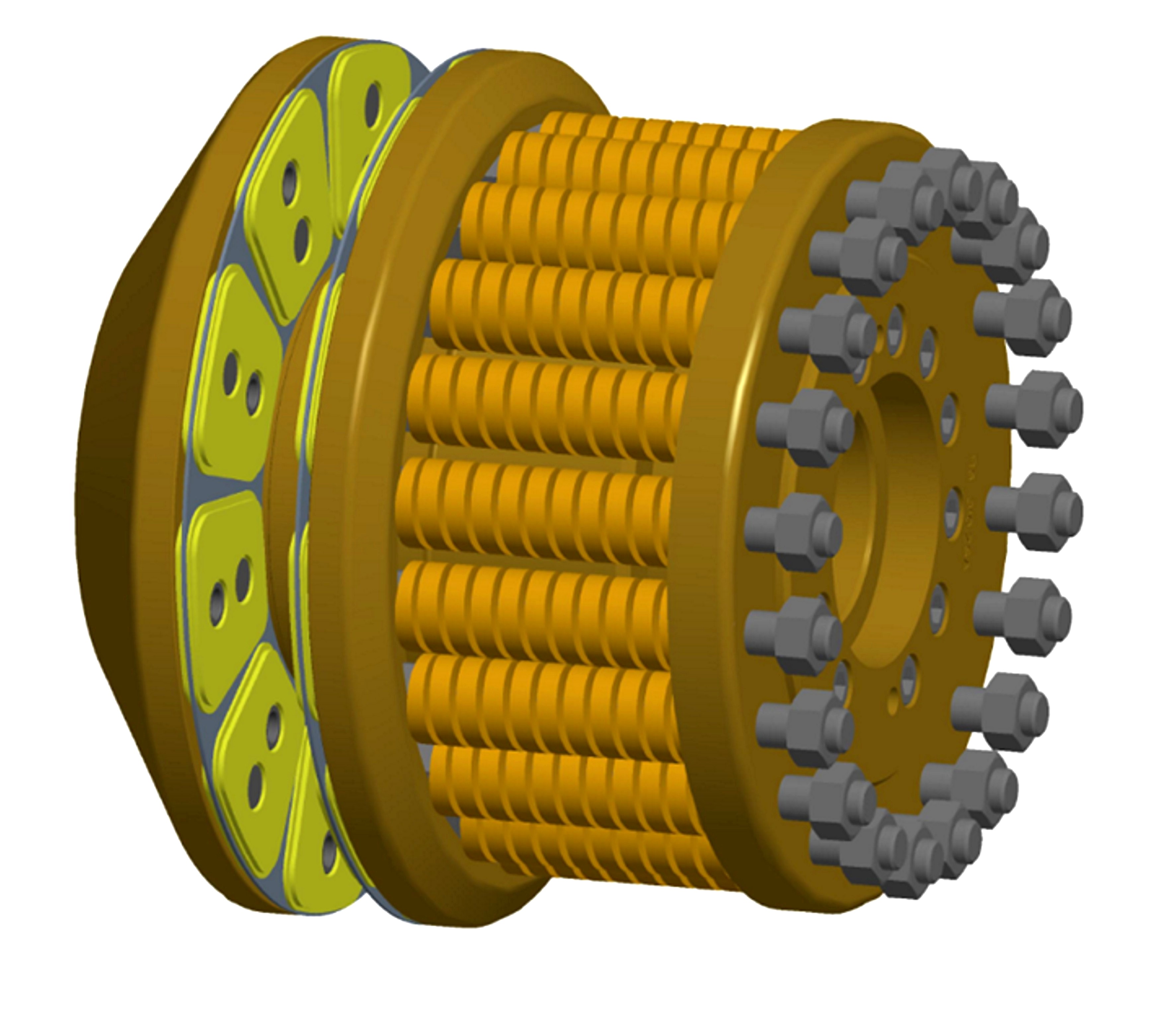

In its RIMOSTAT® series, RINGSPANN realises a design principle that is essentially tailor-made for all applications where greater forces at work. For here it is not disc springs but long ISO coil springs that, with a linear and flat curve progression, produce a contact pressure on the friction linings. The advantage: Even if there is wear to the friction lining, the decrease in the slipping torque (i.e. the crucial performance parameter of a friction torque limiter) is hardly worth mentioning. Since RINGSPANN developers have also fitted the new overload protection with high-performance friction linings made of innovative and fortunately nickel-free sintered material, they have managed to exploit these design advantages far into the upper heavy-duty range. In practice this means: The RIMOSTAT® RSHD earns brownie points for its permanently very high consistency of slipping torque while at the same time offering high temperature stability. Its largest version is suitable for areas of application requiring a slipping torque of up to 60,000 Nm. The plant operator therefore gets an extremely process-stable overload protection with high service lives and maximum safety reserves.

Extreme athlete for five performance classes

RINGSPANN offers designers and development engineers its new "extreme athlete" in five sizes for five different performance ranges. The smallest RIMOSTAT® friction torque limiter RSHD has a diameter of 205 mm and covers slipping torques from 300 to 3000 Nm at speeds of up to 2,700 min-1. In its largest version, the heavy-duty friction torque limiter has a diameter of 600 mm and can be used for slipping torques from 20,000 to 60,000 Nm at speeds of up to 1000 min-1. With all sizes, the user has the possibility of setting the slipping torque to meet his requirement. What is practical is that this is not done by adjusting the pre-stress of each individual spring, but by activating or deactivating complete springs. Where requested by the customer, RINGSPANN will set the slipping torque at the factory – conditional upon the connector to the machine being provided.

Irrespectively of the size chosen, the hub, spring carrier and pressure ring of the RIMOSTAT® friction torque limiter RSHD are all made of high-strength high-grade steel, and the outer surfaces have a corrosion protection coating. As indispensable functional elements for setting the slipping torque and contact pressure, all system springs, screws and nuts used meet the ISO standard. The RIMOSTAT® friction torque limiter RSHD is always delivered fully fitted with springs.

Overload damage to drive units of machines and plants is always a costly annoyance, when and wherever it occurs. For example, such damage can be particularly expensive for operators of hydrotechnical offshore delivery and intake systems in marine engineering. Repair work soon racks up five-figure sums in these areas. In the machines of the building industry and in the shredding mills of the plastic, waste and recycling industry, it equally necessary to prevent potential overloading damages as early as during the design phase. The new heavy-duty friction torque limiter RIMOSTAT® RSHD by RINGSPANN makes a valuable contribution to this.