2017-11-08

”Right in the middle of the frictional locking offensive”

RINGSPANN is consolidating its position as a premium supplier of shaft-hub-connections

On its way towards becoming a one-stop supplier for high-quality power transmission components, manufacturer RINGSPANN has over the course of the last few months also been updating and expanding its range of shaft-hub-connections connected by friction. Find out in this interview with division head Franz Eisele which technological aspects and international market trends the company is hereby taking as a guide – and where the journey is heading.

New premium shrink discs, a re-calculation of all shaft-hub-connection series, and most recently the opening of the RINGSPANN online shop for shaft-hub-connections – it almost looks like a product offensive. Or is this first impression misleading?

Eisele: Not at all, in fact these are all the first results of a product offensive in the field of shaft-hub-connections that we set in motion several years ago. This process is not yet completed; we are currently right in the middle of the frictional locking offensive, so to speak.

You are referring to the friction tight connection, the technical underlying principle of all shaft-hub-connections of RINGSPANN. Will you remain faithful to this principle?

Eisele: Definitely. All our attention is devoted to the ongoing further development of the frictional locking principle. We are also especially focused on the targeted influencing of the key factor, the coefficient of friction. We hereby not only profit from decades of practical experience with users from all around the world, but also from our collaboration with universities within the scope of our activities in the FVA (German Power Transmission Research Association). As a long-time manufacturer of shaft-hub-connections, we also possess well-founded design knowhow in this segment and have our own testing facility for fundamental research and quality assurance. All these aspects, by the way, are what set us apart from dealers.

Do you see additional aspects that set RINGSPANN apart from other shaft-hub-connection providers?

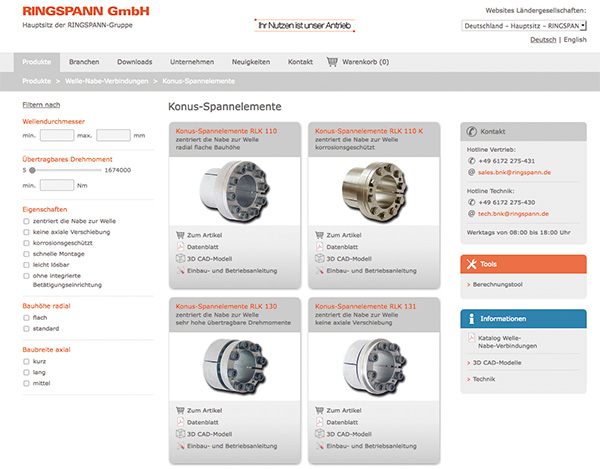

Eisele: We are also able to use synergies with other RINGSPANN product groups for development work in the field of shaft-hub-connections – for example freewheels, clutches or brakes. That is a genuine unique selling point. In addition, there can currently hardly be any other manufacturers who can boast such a wide array of shaft-hub-connections and offer such competent support as RINGSPANN. Design engineers, purchasers and product developers will find all technically relevant designs of shaft-hub-connections connected by friction at RINGSPANN. That is because our portfolio comprises both externally clamping shrink discs and internally clamping cone clamping elements, internally clamping star discs and star spring washers for ball bearing compensation, as well as clamping systems for mounting torque motors. Since 2016 we have also expanded our product range with a number of new products from 18 to currently 25 shaft-hub-connection series for torques ranging from 0.16 Nm to 4,225,000 Nm.

Which new products would that be for example?

Eisele: Our new particularly high-quality type RLK TC premium elements are outstanding. The abbreviation stands for true centring and refers to the extremely high level of accuracy with which these double-slotted cone clamping elements centre the hollow shaft to the shaft. Also new are the attractively priced three-part shrink discs RLK 603 S. The S stands for strong, since these shaft-hub-connections convince thanks to very high power densities. The RLK 608 and RLK 603 series were already added to the product range last year. They are two and three-part shrink discs for the external clamping of hollow shafts with very large diameters. Another overarching highlight is a complete re-calculation of all shaft-hub-connections.

A re-calculation? Was that absolutely necessary?

Eisele: Not necessarily, but our close cooperation with the FVA and the knowledge transfer between our plants in Europe, South Africa and Asia have led to findings that have formed the basis for implementing a new interpretation of the frictional locking values for all shaft-hub-connections. This also serves to underline RINGSPANN’s technological leadership in this field.

What is so special about these new calculation methods?

Eisele: It better reflects reality than previous methods and clearly shows that many of our shaft-hub-connections perform better than previous data tables suggested. To quickly make this new expertise available to all users, we immediately integrated it into the 2017/18 product catalogue and the free online calculation tool on our website. In combination with our new shaft-hub-connections online shop, every design engineer is now able to make quick and precise product comparisons early in the development phase. This prevents errors in design and simplifies the selection process for shaft-hub-connections.

What are the typical mistakes that you see in the application of shaft-hub-connections?

Eisele: Most design engineers in Europe today are very well versed on the issue of shaft-hub-connections; serious application errors are therefore very rare. Issues occasionally arise with hollow shaft connections, which is why we have added the stress analysis on the inside of hollow shafts to our calculation tool. Internationally, meanwhile, there is often still a lack of trust in connections connected via friction lining. This is especially the case in the USA, where we are currently trying to set new trends on the basis of our technological expertise. In Asia, users sometimes lack key basic technical knowledge. This can lead to existing designs being modified without taking into account aspects relevant to shaft-hub-connections.

And yet in practice it is not just the design engineers who are involved in selecting a shaft-hub-connection. Purchasers and sourcing managers also have a say …

Eisele: … and unfortunately, they are often too singularly focused on the price of an element. And yet a shaft-hub-connection normally only accounts for a very small portion of the total costs of a system or machine. More important issues are those of quality, support and international availability! Some customers have recognised this, however, and for example favour our premium elements RLK TC over a standard shaft-hub-connection – despite the higher price. The TCO consideration is often the deciding factor.

How do you react to this – for example in terms of developing new shaft-hub-connections?

Eisele: Precisely because of the TCO, the greatest emphasis is placed on customer benefit. Regardless of whether we are fine-tuning the design, selecting materials, simplifying the assembly or integrating new features. We are always focused on the user – whilst always taking industry-specific preferences into account. We know that external clamping with shrink discs is preferred when it comes to the construction of industrial gearboxes, while mechanical engineering employs many different intermediate clamping solutions with cone clamping elements – to name just two examples.

How much time do you devote to realising customer-specific shaft-hub-connections nowadays?

Eisele: Our wide range of standard products usually offers a perfect point of departure for such projects, providing a basis from which we can realise an optimal solution together with the customer for their specific application. We can hereby pull out all the stops that RINGSPANN can offer as a manufacturer in the areas of development and production. Many customer solutions that were realised in this manner today form part of our shaft-hub-connection product range.

Do you have an illustrative example of this?

Eisele: Amongst our current shaft-hub-connection range are the RTM series clamping systems for mounting and centring integrated and complete torque motors on machine shafts. This is a typical case: These solutions, once developed as a solution for a customer’s specific requirements, have since become a widely applied standard principle.

And finally, we would like to know which developments your division is currently working on?

Eisele: I do not want to give too much away. The fact that many of our considerations are centred around the topic of coefficient of friction has already been mentioned. Since it is the pivotal issue for shaft-hub-connections connected by friction, we will continue to work intensively on this issue. In doing so we are also challenging tried and tested concepts to create innovative clamping elements. We are also increasingly being approached about desires for solutions for new materials. Here it is about working with ceramics or engineering plastics, for example.

Innovative method for precise frictional locking calculation

Coinciding with the release of the new product catalogue 2017/18, RINGSPANN has also updated its online calculation tool with the improved frictional locking calculation method. Here, engineers and buyers can select the technically and in terms of cost best shaft-hub connection for them at the touch of a button. The RINGSPANN tool hereby not only processes all key parameters (hub dimensions, surface pressure, torque, tightening torque etc.), but can also calculate the torque to be transmitted, even under consideration of the axial forces and additional bending moments. All results can be downloaded as a PDF file and CAD models are also available.