2018-07-24

World premiere with precision right down to the thousandth

RINGSPANN presents a new clamping clutch for multiple-axis simultaneous technology

At the AMB 2018, RINGSPANN will once again be showcasing its position as an innovative premium supplier for the international machine tool industry in Hall 3. When it comes to issues of drive and clamping technology, the worldwide active company convinces with high-grade components that help mechanical engineers to realise highly-efficient precision solutions. This time, however, RINGSPANN will not just be exhibiting its precision clamping fixtures, shaft-hub-connections, torque and force limiters, brakes and friction torque limiters – for the first time, a new clamping clutch is also being presented for use in the driven rotary/tilt tables of multi-axis machining centres.

Bad Homburg, July 2018. – When it comes to mastering the three factors of power, dynamic and precision in modern multi-axis machining centres, the construction of workpiece holders and clamping elements play a key role. Continuously increasing demands on achievable accuracies and feasible torques are no longer a real surprise – least of all for suppliers. However, when a renowned mechanical engineer needed a high-precision solution to fix the driven positioning axes of the rotary/tilt table of a new five-axis machining centre, the challenge quickly separated the wheat from the chaff. After numerous manufacturers of clamping fixtures and clamping elements had to decline, the mechanical engineer came to RINGSPANN with its vision.

In the coordinate field of milling machines and machining centres, the rotary/tilt tables or portals form the A and the C-axis. Their function consists in enabling both a precise and quick approach of the workpiece to be processed into any angle setting. To achieve this, the positioning axes with the latest generation of rotary/tilt tables are driven by modern torque motors that can be controlled directly and with a high degree of precision. “And then, as soon as precise angle settings are to be held under stress during the highly precise simultaneous machining, these axes must be held – i.e. fixed. There are already clamping element solutions on the market that achieve this, however none meet the customer’s strict criteria”, explains Volker Schlautmann, the head of the clamping fixtures division at RINGSPANN.

“A real standout product”

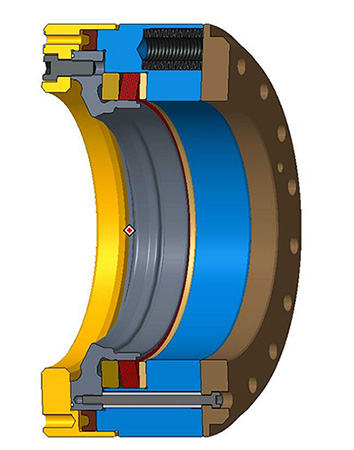

Based on an existing clamping technology concept of RINGSPANN, an interdisciplinary team composed of engineers from the customer and RINGSPANN specialists took on the task. The team developed, tested and finally realised a new clamping clutch that convinced the mechanical engineer. And so, for the first time at the AMB at the RINGSPANN Booth C01 in Hall 3, it will be presented to a trade audience and as a world premiere represents the highlight of this year’s trade fair programme. What is so unique about it: At torques of up to 2,400 Nm, the new clamping clutch guarantees a torsion angle of max. 0.007 degrees! “With these key technical parameters – and particularly with this level of accuracy – our new clamping clutch for rotary/tilt tables is a real standout product amongst the known fixing elements in this segment”, stresses Volker Schlautmann.

At RINGSPANN’s AMB booth, trade fair visitors can have the operating principle of the new clamping clutch explained to them. One of the things they will discover is that it employs clamping discs from the RINGSPANN range to transfer the axial force of pressure springs into a radial force and feature a specially designed deformation element. “In this manner, we ensure the torsionally stiff clamping of the kingpin. The clamping is then quickly released by applying hydraulic pressure to the clamping clutch. The torque motor can subsequently freely drive the axle into any other angle setting”, explains Volker Schlautmann.

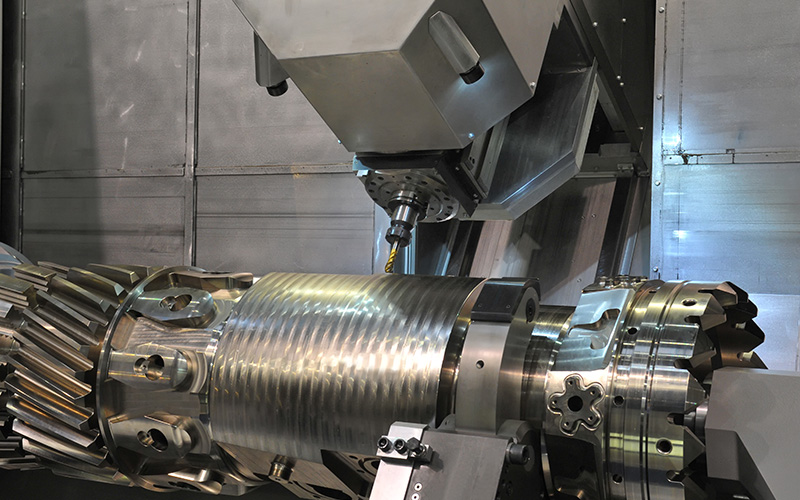

The new clamping clutch for rotary/tilt tables is now being produced in series and further enriches RINGSPANN’s clamping technology portfolio. At the AMB, the company will however also be showing countless other components from this segment. Among them are precision clamping fixtures for the mechanical processing of cylindrical internal and external surfaces, which are widely available as standardised complete clamping fixtures. They are available in nine versions, so the customer can choose from four flange chucks and flange mandrels in the construction forms bonded disc, taper collet, taper sleeve, flat element and a taper collet centre mandrel. With true running accuracies of ≤ 10 µm, these clamping fixtures are ideally suited for demanding tasks in machining technology.

The next highlight that RINGSPANN will be showcasing is the expanding sleeve mandrel HDDS developed in 2016, which represents an economically attractive alternative to hydraulic expanding clamping tools in gearing technology and fine machining. It stands out thanks to true running accuracies of ≤ 5 µm, can take up workpieces with bores of up to tolerance class IT10 and reduces the costs for feeding and positioning technology in fully automated operation. The HDDS range has since been augmented by an additional, smaller expanding sleeve mandrel, which means that bores from diameters of 22 mm (previously 32 mm) can now also be clamped.

Comprehensive range on display at the AMB

At this year’s AMB trade fair stand, RINGSPANN will not only be presenting innovative components from its clamping technology division, but will also be inviting visitors on a foray through its other product ranges for the machine tool industry. Because, as should be common knowledge by now, RINGSPANN offers among other things a wide selection of technical solutions for the secure operation of the main and auxiliary drives of tool machines and machining centres. Successful examples of this are the form-fit SIKUMAT® positive torque limiters and RIMOSTAT® friction torque limiters connected via friction lining. As overload protection for machine tool drives and spindles, they are ready for installation with various limit torques (0.5 – 10,000 Nm) and speed ranges (1,000 – 13,000 min-1) to choose from. As overload protection for push rods und drawbars, meanwhile, RINGSPANN’s bi-directional acting force limiters are suited for disengaging forces of 3,600 – 140,000 N. A selection of overload clutches will also be on display.

A further focus of this year’s AMB trade fair range is RINGSPANN’s shaft-hub-connections connected via friction lining. Engineers and purchasers in the machine tool industry will find representative examples for all technically relevant types of these connection elements: externally clamping shrink discs for a play-free connection of hollow shafts and hubs on shafts, internally clamping cone clamping elements for the frictional connection of hubs on shafts, internally clamping star discs for applications with frequent switching between clamping and release, and star spring washers for the compensatory tolerance of ball bearings. Clamping systems for fixing torque motors on machine shafts connected via friction lining can also be found in this range. In total, RINGSPANN’s shaft-hub-connections cover torques ranging from 0.16 Nm to 4,225,000 Nm.

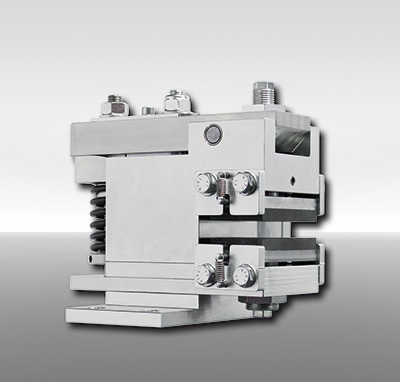

Since RINGSPANN has also significantly expanded its brake range in the last few months on its way to becoming a one-stop supplier for high-grade components in drive technology, machine tool manufacturers at the company’s AMB booth will also find numerous exponents from this segment. The electromagnetic disc brakes, which can be used for braking, holding and emergency stopping gravity-loaded and driven axles both from linear axles and rail guides, are bound to be a particular eye-catcher. The electromagnetic disc brakes from the EV and EH ranges particularly convince with lean installation dimensions, high degree of energy efficiency, low weight (from 6.5 kg) and numerous Industry 4.0 features (e.g. sensory monitoring). In the field of electrical brakes, RINGSPANN currently offers 16 basic types in four frame sizes with clamping forces ranging from 1,800 to 24,000 N; across all technologies, however, the industrial brake portfolio of the company covers braking torques from 0.5 to 600,000 Nm!